Materials

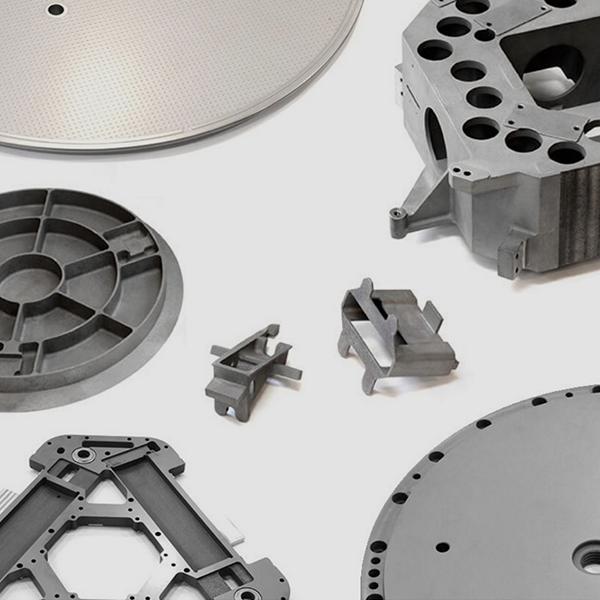

Reaction-Bonded SiC

Source RB-SiC components of nearly any size or shape, customized as needed, including high flatness, large infiltration depth, and internal cooling channels.

RB-SiC offers a unique combination of physical characteristics - high-temperature resistance, low CTE, chemical inertness, high strength, and strength-to-weight ratio - for applications in high-voltage electronics, semiconductor tooling, and more.

By providing your information and clicking ‘Subscribe’, you opt-in to receiving periodic email marketing communications from Coherent Corp. and understand that your personal data will be processed in accordance with our Privacy Policy and that our Terms apply. You may opt-out of marketing emails sent by us at any time by clicking the unsubscribe link in any marketing email you receive.

Reaction Bonded SiC Properties

Choose from a range of RB-SiC substrate materials optimized for various mechanical, thermal, and electrical characteristics.

Property |

SSC-702 |

SSC-802 |

SSC-902 |

SSC-HTC |

SSC-FG (Fine-Grained SiSiC) |

HSC-702 (Si/SiC+Al) |

TSC-15 (Si/SiC + Ti) |

RBBC-751 (B4C/SiC/Si) |

SiCAM 700 |

SiCAM 800 |

SiC Content (Vol. %) |

70 |

80 |

90 |

78 |

70 |

70 |

80 |

70B4C 10SiC |

70 |

80 |

Si Content (Vol. %) |

30 |

20 |

10 |

22 |

30 |

30 |

20 |

20 |

30 |

20 |

Bulk Density (g/cc) |

2.95 |

3.00 |

3.12 |

3.02 |

2.94 |

3.01 |

3.13 |

2.56 |

2.95 |

3.00 |

Young’s Modulus (GPa) [E] |

350 |

380 |

410 |

373 |

330 |

330 |

390 |

400 |

345 |

365 |

Poisson’s Ratio |

0.18 |

0.18 |

0.18 |

0.2 |

0.18 |

0.19 |

0.19 |

0.18 |

0.185 |

0.185 |

Flexural Strength (MPa) |

270 |

280 |

280 |

265 |

350 |

275 |

225 |

280 |

280 |

290 |

Fracture Toughness (Mpa-m1/2) |

4 |

4 |

4 |

3.5 |

4 |

5 |

5 |

5 |

3.2 |

3.2 |

CTE (25-100°C) (ppm/K) |

2.9 |

2.9 |

2.7 |

2.9 |

3 |

4.4 |

3 |

4.8 |

3.2 |

3.1 |

Thermal Cond. (W/mK) |

170 |

180 |

190 |

402 |

150 |

200 |

210 |

52 |

177 |

185 |

Specific Heat (J/kg-K) |

680 |

670 |

660 |

670 |

680 |

700 |

670 |

890 |

686 |

674 |

Specific Stiffness (E/ρ) |

119 |

127 |

131 |

- |

112 |

109 |

125 |

156 |

117 |

122 |

Thermal Stability (k/α) |

59 |

62 |

70 |

- |

50 |

45 |

70 |

11 |

55 |

60 |

Related Products

Featured Blog

SiC Circuitry Makes EVs Better

Coherent is one of the few companies worldwide with a complete, vertically integrated SiC manufacturing capability. We produce SiC wafers and epitaxy, all the way through power devices and modules. Furthermore, the unmatched quality with which we can produce SiC material makes Coherent virtually the only supplier positioned to successfully transition from the current standard wafer diameter of 150 mm up to 200 mm.

Featured Success Story

Laser Framework Makes a Mark in Siemens’ Digital Factory

Coherent applications development support and Coherent Laser FrameWork software enable Siemens to successfully implement their ID Link manufacturing program.