Laser Machines and Systems

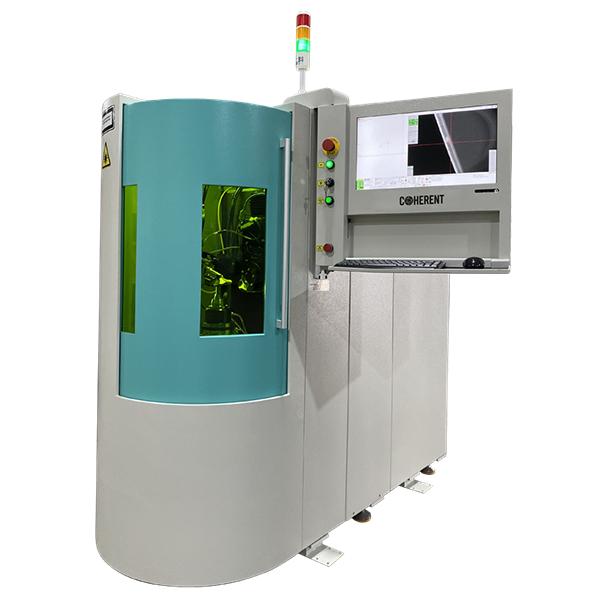

Q60 – Economical Cutting of Superhard Materials

Get the ideal combination of speed and economy for cutting polycrystalline diamond (PCD), cubic boron nitride (CBN), and carbides with these powerful laser systems.

PCD, CBN, and carbides are notoriously tough to cut. Q60 machines are ideal solutions thanks to a powerful, low-maintenance 600-watt fiber laser. The Q60 is available in an economical three-axis version (Q60-3x), plus 4- and 5-axis models (Q60-4x and -5x).

By providing your information and clicking ‘Subscribe’, you opt-in to receiving periodic email marketing communications from Coherent Corp. and understand that your personal data will be processed in accordance with our Privacy Policy and that our Terms apply. You may opt-out of marketing emails sent by us at any time by clicking the unsubscribe link in any marketing email you receive.

Q60 – Specifications and Options

Choose 4 or 5 axes for variable-taper or taper-free cutting. All machines use coaxial video and machine vision monitoring. eMicro software simplifies machine operation.

Product Specifications

Model Number |

Laser Details |

Number of Cutting Axes |

XY Table (mm) |

Rotary Table Option |

Max Traverse Speed (mm/s) |

XY Fixture Area (mm) |

Overall Dimensions (WxDxH mm) |

Q60-3x |

600 W fiber laser Wavelength 1060 nm |

3 |

300x300 |

N |

50 |

250x300 |

940x1680x1770 |

Q60-4x |

4 |

Y |

250x100 |

1300x2050x1800 |

|||

Q60-5x |

5 |

Y |

250x100 |

1300x2050x1800 |